What goes around…

June 29, 2007

Early last century a man of Russian nobility came to the United States. Little is known about him, but his nobility and loyalty to Czar Nicholas seem to be beyond question. By a circuitous route he came to Milwaukee where many of his countrymen had settled. His true name is unknown, having taken another. He plotted to take back his Mother Russia from the Bolsheviks, but was poisoned, or assassinated, depending upon who you ask. He gave birth to daughters, one of them named Alexandria, his son Nicholas having died at birth. Alexandria, known throughout her life as “Alice”, gave birth to Bernadine, and Bernadine to Arthur. Alice, Bernadine and Arthur never knew the Russia of their forefather.

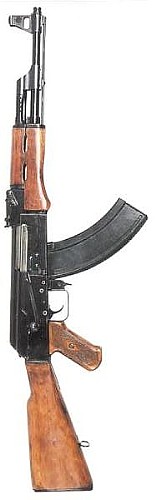

In the closing days of the World War II, (or “The Great Patriotic War” as it is known to a Soviet) a Russian soldier wounded in the Battle of Bryansk convalesced in a hospital. That man’s name was Mikhail Kalashnikov. During his convalescence he designed a rifle that would someday become the most successful and prolific battle rifle of modern times: the AK47. Not only was the rifle successful as a weapon, but it became an icon of sorts symbolizing communism worldwide. Few Cold War symbols were stronger or better recognized than the AK47. As it turns out, as you well know, the Cold War ended and Communism died in the former Soviet Union. Trade opened up with Russia and things such as the civilian version of the AK47 made it to or shores.

Arthur has been a shooter since he was old enough to shoot. Bernadine had a strong say in how old that was. One of the rifles that Arthur owns is the Russian made civilian version of the Mikhail Kalashnikov’s AK47, one made at the renowned IZHMASH factory. While Arthur thoroughly enjoys shooting the rifle it also stands as a reminder to him that all things are possible with time and perseverance. It’s also a reminder of his ancestry.

Yesterday while moving some boxes Arthur leaned the AK rifle up against a desk. While he thought the rifle was solidly in place it started to slide in an arc rapidly towards the ground. The rifle never hit the ground. No, the rifle landed squarely on Arthur’s barefooted left big toe. The excruciating pain was immediate resulting in a five minute waltz around the room speaking in tongues the likes of which have rarely been uttered. As the pain resided to mere agony Arthur tended to his rifle finding the Cold War icon unmarked and undamaged. No worse for the wear, and despite relief at finding it so, it’s resiliency seemed to mock him and his battered White Russian left toe.

As I stood in my workshop holding the rifle, toe throbbing, I had this image of my great grandfather rolling his eyes saying “figures”, and another of Mikhail Kalashnikov saying “serves him right.” I’ve had a good chuckle over it.

Problem is that it only hurts when I laugh.

Ironic. Nyet?

Thanks

June 29, 2007

I’ve written a bit about my Dad here in ShopTalk, and one thing that I failed to mention is that he was a very generous and giving man. As a dentist he would give discounts to folks who he felt gave through their work well beyond the compensation that they received. When he retired he received a very rare official thank you from the Pope. He had never charged clergy for his services, and only asked for the payment for his lab fees, and he had the lab take a deep discount.

I’d like to think that the apple didn’t fall too far from the tree. So, I am going to follow my father’s tradition and offer a discount to the same folks that he, and I, believe should be shown our thanks for the important and relatively underpaid jobs that they do.

From today forward the following folks will receive a 10% discount on any Ming, Kaze, Moxie, Destiny item that I sell: teachers/librarians, clergy, police/law enforcement, firefighters, veterans, and active military.

This discount is not available on sale items, on reduced items, or with any other discounts or specials. It applies to retail items up and already available on the site. With special orders I will price accordingly reflecting this general notion. It will be up to you to mention the discount, and please do.

Whether you use this discount or not, I would like to thank you for the job that you do. We’d be lost without you.

Finally…Pablo!

June 25, 2007

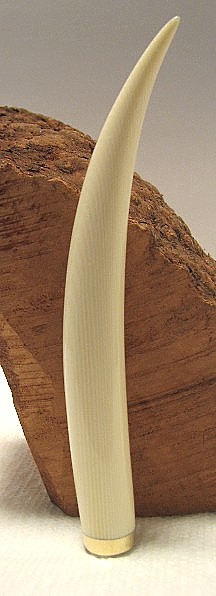

(shown rough carved)

A few years or so back I decided to sculpt a very unique single tamp stand. A customer put it on hold, and the piece bumped around for a while, got lost, and now got found. I was torn as there was a problem with it. The chamber had been drilled at a slight angle, and with something that will be as clear (more clear, actually) than glass it would be noticed. So, I let the piece languish.

Since then I have increased the diameter of my chambers, so when I recently stumbled across it again it hit me that by re-drilling the chamber in the current larger diameter it would encompass the old chamber replacing it with a straightly aligned one. It worked.

So, now the piece has been sanded and is ready to be buffed. I call it “Pablo”. I love this piece, and when it is finished you will see it here from numerous angles. It may be taken or not, but I’m offering it at the original price of $175 from years ago. That only seems fair although a piece like this could go for far more, especially with the corrected canted chamber. As this piece was water sanded I have a very good idea what it is going to look like crystal clear, and it is going to be one piece of work. Look for photos later this week. By the way, despite what you see the overall shape is a cube.

P.S. I just heard from the original customer. Pablo is now sold.

Totally Rad- Part II

June 20, 2007

Now that the Chicago Show is behind us what follows is part II of my interview with pipe maker Rad Davis. This time I varied things a little with a number of different questions. Remember, your follow-up questions are welcome and can be submitted through comments below or via email at mingkahuna@aol.com.

ME: Rad, I heard you had a fantastic Chicago show. That’s no surprise to anyone. Heaven knows that I could have sold five times over those two blast Chicago pipes that I posted with the last blog piece, Part I of this interview! I know that many of us use the Chicago show as a time to take a good look around and plan for the following year. Is that true with you?

RAD: Not necessarily. If there is a lot of buzz about some fantastic new shape, then of course, I’ll try to get a look at it to see what all the fuss is about, but it will usually turn out to be something beyond what I am able to do at the time. As far as taking a good look around, the few spare moments that I do have away from my table give me very little time to take much of anything in, and I’m usually socializing more than looking anyway, even though I’m really trying to look. I don’t really plan for anything as far as what I’ll be doing for the next year other than I know I’m going to be making pipes.

ME: What kinds of directions or goals have you set for yourself that you’d be willing to discuss?

RAD: As far as shapes go, I have no direction other than making what I like to make and trying new shapes as the inspiration hits me. My goal is to always improve my work. I’m always working on sharper definition at the bowl/shank join and fit and finish and refining shapes. I think the biggest improvement over the last year for me has been the fit between shank and stem. After making over 1,000 pipes, I have finally gotten it where it’s almost seamless. It still could get better, though. Another thing is I have gotten much better at getting the drilling where I want it very consistently with the smoke hole dead center and on the bottom. I still get it a bit off to the side sometimes when drilling a long shank, but for the most part, I have been able to get the drilling dead on. At a certain point in pipemaking, improvements become all about small details, and those small details can really make a difference in how a pipe looks and feels in the hand and mouth. I learn something with almost every pipe I make.

ME: What really caught your eye at the show and what new directions or trends, if any, do you see?

RAD: As I said, I don’t really have a lot of time to scope out the show. I man my table by myself, and any time away from it is short. As far as trends go, I don’t really pay much attention.

ME: For a typical day that you will be working in the shop, share with us, in as much detail as you are willing and able, a day in the life of pipe maker Rad Davis.

RAD: I’m usually in the shop by 9 AM Monday thru Friday, and I work until 5pm. If I have a custom order, I’ll work on that. If not, I’ll look for a block with nice grain and sit down and decide what I want to do with it. I’ll draw a shape on the block, cut it out on the bandsaw, drill it, and cut a piece of rod for the stem. I drill the rod, cut a tenon to fit it to the pipe and start shaping away. I try to get a pipe finished before lunch, but this doesn’t always happen. After lunch, I’m back at it again to try and get a second pipe made, but this doesn’t always happen either. I average about 1 1/2 pipes per day. I absolutely love making pipes. It’s fun, challenging, there’s always something new to try, and I feel very fortunate to be able to make a living doing it. There’s nothing better than being able to make a living at doing something you love to do. It’s like you’re not really “working” at all.

(Be sure to check back here for Part III!)

Lessons

June 19, 2007

This past Father’s Day I got to thinking about my Dad. He was a good man who lived a good life. He died back in 1987, and I miss him. He was a pretty hard-headed guy with strong opinions, but that was just fine as he had a lot of knowledge and common sense, and opinions that were worthy of strong consideration. One event always sticks out in my mind, a fun moment when I saw my Dad speechless but able to teach a lesson nonetheless, one that has never been forgotten.

Back in 1976 when I was heading off to college my Dad told me that it was time to buy a suit. He didn’t tell me to buy just any suit, but he said that it should be a good suit. So, one Saturday I went to his clothier, Christian St. John, and bought a suit. I had charge card in hand, and a mission to accomplish!

Some hours later I returned home, the suit with the tailor being altered. With a 49 inch chest and a 31 inch waist (ah, the good old days!) no suit would fit me off the rack. As I walked into the house my Dad asked me whether I had bought a suit. I responded in the affirmative. He then asked me if I had bought a “good” suit. I again responded in the affirmative as I handed him the receipt. As my father unfolded the crumpled up wad and saw the price his eyes widened (in a cartoon they would have popped out of his head with a “Boing!” sound) and he sat down hard on a kitchen table chair staring in utter disbelief at what he saw. This stunned silence went on for a good while as I stood there wondering what I had done. Then, my Dad looked up at me briefly, reared back in the chair with his face towards the ceiling, and let out a belly-laugh like I had never heard before. He laughed until he cried. Finally, as the laughter subsided, he spoke.

He looked me straight in the eye and said to me “Well, I told you to buy a good suit, and that you did.” In defense, I knew nothing about suits and what they cost. I only knew my mission, and I had communicated my exact goal to the salesman (who must have been elated, to say the least) who knew my family well. What I had done was to buy one of the finest non-custom made suits going, a Bill Blass that was three or four times the price of a typical “good suit.” This was 1976 and I had chosen a $650 suit when a more typical price might have been $150. To top it off I added to the suite a pair of charcoal gray pants for a more “casual” look, perfect for the very unlikely event of an afternoon tea with the dean. I suppose that today the equivalent would be coming home with a $2000 suit.

So, standing before my Dad realizing that I had made a major error, and that I wouldn’t get scalped for it, I decided that the best course was to eat a little crow. To that end I commented to my Dad that I should have bought a more “affordable” suit. The smile disappeared from my Dad’s face, and I could tell that a lesson was about to be imparted.

My Dad leaned forward (I had since taken a seat across from him at the table) and he asked me why I assumed that the suit wasn’t affordable. I responded that it wasn’t affordable because it was very expensive. My Dad’s response was to say “nonsense”. Affordability is only relative to a person’s ability to pay the asking price. He told me that what is affordable to one man may not be to the next, and vice versa, and unless one knew what was in someone’s wallet the issue of affordability was no one’s business and a totally worthless observation that has absolutely nothing to do with the value or worth of an object.

Of course my Dad was right. He could indeed afford the suit. He was a successful dentist and oral surgeon who worked long and hard for what he had. And while it might not have been a suit that could be bought by someone who earned much less than my Dad, there were people who could buy suits that were beyond my Dad’s means. The bottom line was that judging the suit in terms of affordability was meaningless as to the suit itself.

I was a little slow that afternoon and for some season I saw the need to try another helping of crow, so I responded to my Dad that paying $650 for a suit wasn’t reasonable. Again my Dad leaned forward in his chair, and another lesson was about to be taught.

After long consideration, looking to put it in terms that I could easily understand at my age and experience in life, my Dad asked me why I thought $650 wasn’t a reasonable price for a suit. That was easy, $650 was a lot to spend when other suits could be had for less. My Dad just shook his head and sat back in his chair pondering what I had just said. After a few long moments he began.

“How much does a Corvette cost?” I responded that I thought one could be had for around $8600 (or whatever it was back then). He then asked what a Chevy Vega went for. I told him that one could be had for $2400. He then asked me why the Vette cost so much. I told him that it was a special high performance car that was more expensive to build and was more desirable. He then asked me why the Vega was priced as it was. I told him that I supposed that it was more cheaply made, wasn’t high performance and was not as desirable a car. My Dad then asked me whether the Vette was reasonably priced. I told him that I thought that it was. The same question and answer passed between us regarding the Vega. It was indeed reasonably priced. My Dad then told me that if I was to apply my logic used in determining whether my suit was reasonably priced to the automobiles that I would always have to respond that the Vega was reasonably priced and the Vette was not. I think that at that point a little light bulb must have gone off over my head as I then said to my Dad that the value of something, or the reasonableness of its price, should be determined by its own value and not strictly by a comparison with something of different value. The smile returned to his face.

He told me that was correct. A $100 suit could be reasonably priced for what it was if you looked at what it was and judged it on its own merits just as the $650 suit could be reasonable based upon the suit itself. To assume the expensive suite to be unreasonably priced because it was priced higher was to turn one’s back on the very ideas of merit and worth. The Vega, or a far less expensive suit, might be very reasonably priced for what it was. Equally, a fine suit might be worth every penny of $650 and more, but the fact that it’s priced considerably higher does not make it unreasonably priced, nor does it make the less expensively priced suit reasonably priced by default. Just as with the Vega, and the Vette, the two suits stand on their own as to merit and price, and to determine reasonableness by comparison only confuses the issue.

As it turned out that suit, a spectacular piece of clothing, served me well for many years to come. Less expensive suits came and went, but that one suit served me through college, through law school, and through my first law job as a law clerk. $650 was a lot of money, but I got my use out of that suit, and more than my money’s worth, many times over. The suite was very expensive, and, as it turns out, very, very reasonably priced.

That is a lesson that I have never forgotten. It was nice hearing it again from my Dad, if only in memory, on a very hot Atlanta afternoon, the very kind of afternoon that my Dad (and his son) like best.

First Simba

June 13, 2007

Here is the first tamp offered in Simba, a Dynasty Grade piece. It sold in a heartbeat. The good news is that I can make more Simba tampers. This one is a shape that I call a Tusk. (The listing for it may still be up at the Ming site.) Appropriate name, eh? This really isn’t a new shape for me. I’ve done a number of Tusks and many, many horns over the years, but, never with Simba! Look at the grain on that! It looks so much like elephant ivory that I’d be hard pressed to tell the difference. Plus, it has the warmth of cellulose acetate. On the side shown the grain is more uniform, but on the other side it is a bit more variable adding to the realism. On the top edges you’ll find that wonderful cross-hatched matrix that really wows me with elephant ivory. The folks at Mazzuchelli who developed this material years ago were right on their game. Oh how I wish that I had more Simba.

So, now that I have introduced Simba to the line-up I envision tamps in the following shapes: Tusk, Whisper, Bluto, Dart and possibly the Predator, Proteus and Incubus. I’m open to suggestions on that. I’ll just have to see what happens. Unfortunately there won’t be many of any one shape made as the supply of Simba is so darned limited.

BTW, you may have noted with the first Simba piece shown back on May 14th that there was a darkening at the transition of the material to the brass due to material transparency between the grain. As you can see I have solved that problem.

I hate to say it, but this material won’t be around for long unless I can find more, but the chances of that are slim. If Simba interests you get with me now for a special order.

FYI! Seeing a Dynasty Grade piece on my site today someone asked me how long the Dynasty Grade has been part of Ming-Kahuna. The answer is that I first created the grade back in 1998. Since then I briefly had “Carver’s Choice” which really wasn’t a grade at all, and now the most recent and final grading system: Prefect, Mikado, Dynasty and Apex. KazeTamps and Moxies aren’t graded. I would estimate that only between five and ten percent of tamps make Dynasty. Since introducing the Apex grade back around 2001 or so only ten pieces have made the Apex grade.

Free Genarlow Wilson

June 12, 2007

Now.